Why Every Healthcare IT Team Should Be Moving to the Modular Solutions Architecture for Barcode Scanning Platforms (Especially If New Barcode Applications are Needed and Remote Management Capabilities Matter)

Some say the barcode has become the heart of clinical workflows, and that’s hard to argue against. Barcode scans have become the best practice for positive patient identification (PPID), accurate medication administration and more in hospitals, ambulatory surgical centers, diagnostics centers, and pharmacies. They have also become the primary means for updating electronic medical records (EMR), healthcare information systems, and even healthcare schedules.

Mistakes and missing data both degrade the quality of care a patient receives and disrupt continuity of care, yet they’re common with manual data inputs. It’s also easy to misread information on a patient’s wristband, medication bottle, IV bag, or EMR. Though clinicians are superheroes, they’re also human like the rest of us. Their eyes can deceive them, especially when they’re in a hurry or wrapping up a long shift. What might look like 80 mg might actually be 30 mg, and there are many drug names that are similar in spelling. Likewise, it’s hard to uphold the “five rights” of medication administration – right patient, medication, time, dose, and route – or maintain patient privacy if it’s not easy to verify the details of the doctor’s order against the medication or patient in front of you.

So, clinicians have increasingly come to rely on barcode scans to verify they’re taking the right actions for the right patients at the right time – and reporting the right data into each patient’s EMR. However, doctors and nurses aren’t the only ones who depend on barcode-based data to do their jobs efficiently and effectively.

The Depth of the Barcode “Data Lake”

Nearly every member of the healthcare community will either need to scan a barcoded item or retrieve a record created from a barcode scan at some point in their day. For example, supply managers will use barcode scans to count stock and monitor inventory utilization rates. Lab technicians will scan the barcoded label on inbound and processed specimens to ensure the right test data is being correlated and reported against the right patient record. And the billing department will use data collected via barcode scans of patients’ wristbands, medication labels, medical device packaging, and more to process insurance claims.

I could go on and on about the role barcodes play in healthcare today – how even radiologists, pharmacists, and porters use barcode scans for PPID, reporting, and tracking purposes – but you know how important they are. So, let’s talk for a moment about why barcode scanning solutions are not as pervasive as they should be in hospitals, clinics, and other facilities.

What’s Holding Back the Expansion of Barcode-Based Workflows?

Making barcode scans a requirement before key actions are taken could certainly help to reduce the number of medication administration and lab reporting errors still occurring each year. It could also help speed up clinical workflows without compromising patient safety or privacy. In fact, it would help preserve both. So, why is anyone still manually or verbally verifying patient identification, medication orders, or lab orders? Why isn’t this simple, trustworthy verification solution the standard for PPID, specimen collection, medication administration, EHR management and more in every acute and non-acute facility around the world?

Some might say that it’s an adoption issue; that barcode scanning technologies are deployed but aren’t being used like they should.

However, after talking to healthcare IT leaders and administrators, I realized that healthcare systems may be the ones that are hesitant to adopt more barcode-based applications because one of four things is likely happening:

It seems difficult to integrate a new scanning application into the existing healthcare IT architecture without messing with the EMR application – which no one wants to do. So, they decide to find a workaround, or stick with what’s (probably not) “working” today, thus delaying process improvements that can improve patient and staff experiences.

Barcode scanners may be widely deployed, but when they go missing or stop working, it takes a while to get one back in place or online. Or critical hardware and software updates are being delayed because there’s never a good time to take scanners offline and, at some point, the scanning solution stops working as it should. (At which time they troubleshoot and resolve because the scanner is already offline.)

Larger healthcare systems don’t know what type of barcode scanners they have on every cart/workstation on wheels (COW/WOW) or lab and pharmacy countertop, much less the status of each scanner. (This typically is the result of rapid growth, fragmented modernization efforts across different departments, or acquisitions of other healthcare systems.) Until they can audit what’s where, they hold off on further application development and deployment.

There are barcode scanners available, but they are in an outdated setup called HID Keyboard required by the EMR app and, unfortunately, this outdated setup only supports a one-way data flow – from the scanner to the EMR app.

It seems like the biggest barrier to barcode application adoption centers is that no one has had a solution to all these problems. That’s why I went to work with my team to solve each of them – landing at a single solution that we call the Modular Solutions Architecture.

How a Modular Solutions Architecture Makes It Easier to Manage Barcode-Based Applications Throughout Your Devices’ Life Cycle

Every time you need to push a firmware update, you probably have to take the scanner offline for a good 15+ minutes, right? In fact, you probably can’t do much to manage the device without taking it offline, as data collection (EMR) and remote management modules typically conflict with one another. And I would bet your current applications conflict with one another, meaning you can’t run a query via one without locking out the others.

Additionally, you may not be able to route barcode data to two different information systems simultaneously from a single scan. If you want a record of medication administration to go to both the EHR and a second cloud endpoint for later auditing in the context of workflow efficiency, inventory management or care management, then the clinician would have to scan every barcode in that medication administration process twice.

Well, the good news is that ALL the pain you’re feeling today can go away in an instant. (Well, by tomorrow.)

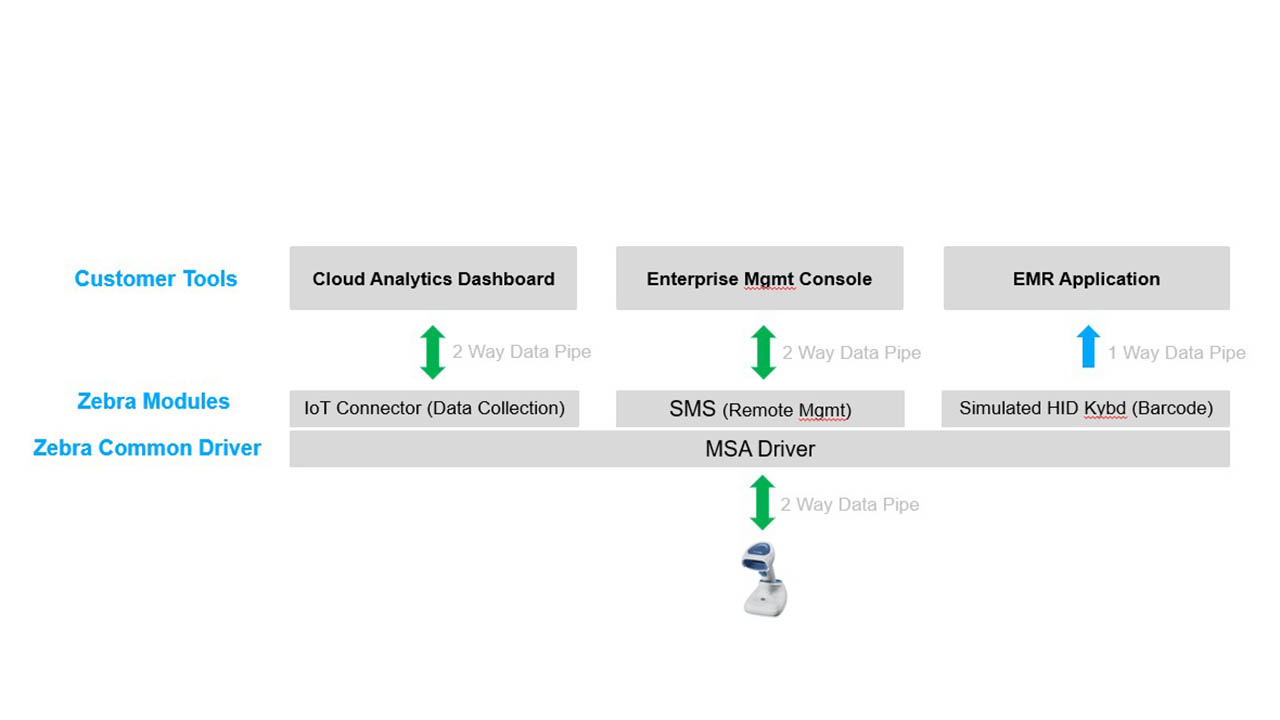

My team and I found a way to put Zebra DataCapture DNA to work for you through Zebra’s Modular Solutions Architecture. Now you can introduce or adapt scanning-based workflows anytime, without doing anything more than downloading a driver and an XML config file then loading in the module you need to support the workflow. That’s right…you can enable your scanning hardware to do more and keep up with your changing enterprise needs – without having to develop a single thing – all within Zebra’s Modular Solution Architecture!

Better yet, all the modules can co-exist and function without conflict. So, nothing will hold you back from moving forward with new barcode scanning applications. In fact, once you move to Zebra’s Modular Solutions Architecture, it becomes possible to do many things that were never possible before now. For example, in many industry firsts, you can now…

perform multiple actions simultaneously, like collecting the cordless scanner’s battery health statistics and configuring the scanner by disabling a symbology while a nurse scans a patient’s wristband ID. (The scanner can now communicate with multiple applications simultaneously without losing communication with your EMR.)

route barcode data to a cloud endpoint via the IoT Connector module while also scanning into your EMR. (Duplicate data records can be sent to a cloud endpoint like Splunk or a data lake for trend analysis and managing inventory – to help ensure positive patient outcomes – while simultaneously being scanned into the EMR app. So, each department can now access every piece of scan data to suit their needs.)

configure your device for scanning into different EMR windows without any nurse intervention required. (Whether scanning into an EMR’s medication administration or operating room implant screen, Zebra’s Modular Solutions Architecture can automate scanner configuration.)

actively respond to Virtual Tether alarms that no one can audibly hear. (If a scanner accidentally got buried at the bottom of a laundry pile when patients’ linens were changed, the alerting system may go unnoticed. The IoT Connector module can pick up this event and send a real time alert to your Splunk or other cloud analytics dashboard to text your on-duty nurse manager.)

In addition to these many industry firsts, Zebra’s Modular Solutions Architecture also enables you to...

download scanner firmware updates hospital wide without taking your scanner offline. (Simply update your scanner to support the newest patient care workflows using the Remote Management module.)

perform an asset query with the click of a button to confirm the location, model, firmware version, and use status of all deployed scanners. (It doesn’t matter when or where they were originally deployed, you’ll be able to confirm their current facility, floor and even room location via the Remote Management module.)

monitor scanner uptime. (Make sure your scanner is ready to meet your needs by regularly checking stats such as battery charge and battery health via the IoT Connector Module.)

In other words, you’re getting more out of your scanning hardware through Zebra’s exclusive Modular Solutions Architecture by….

getting the information needed to maintain accurate patient records, help maintain scanner uptime, manage inventory, and track workflow and worker performance every time a barcode is scanned.

gaining more control over scanners hospital/enterprise wide.

How to Setup Zebra’s Modular Solutions Architecture

All the tools you need to migrate to the Modular Solutions Architecture (MSA) are part of the DataCapture DNA software suite that comes with the purchase of your Zebra scanner.

All you need to do is load the Zebra MSA Driver, configure the XML file for each module you want to add to the MSA, then drop in the modules. No development is required.

If it seems too simple to be true, it’s not. I recently worked with a large healthcare system to set up their MSA. They have tens of thousands of Zebra scanners deployed across their hospitals, which could become an IT nightmare without the right data insights and tools in place. But fleet wide management became a dream thanks to the flexibility of the Zebra Modular Solutions Architecture. They were able to drop in both the Remote Management and IoT Connector modules and immediately open a two-way, automated data pipe between their back-end systems and front-line scanners. Within minutes, they had enterprise-level visibility into their locally deployed scanners. This new insight led to the realization that with one firmware update they could add UDI parsing, blood bag parsing and Virtual Tether to their scanners. Now the scanners are setup for the latest healthcare workflows and monitored in real time to maintain fleet uptime.

Ready to Move to a Modular Solutions Architecture for Your Scanning Solutions?

You can learn about how to construct an MSA by setting up a call with the Zebra scanning solutions team. They'll walk through your current and ideal architecture. I also encourage you to sign up for Zebra Evolution Updates, which detail the new DataCapture DNA releases each quarter, all of which can easily be dropped into your MSA. (Simulated HID Keyboard, Remote Management and IoT Connector aren’t the only ones available today.)

###

Related Reads:

Ken Bhella

Ken Bhella is a Senior Product Manager within Zebra's Data Capture Solutions (DCS) division, responsible for remote scanner management, device setup (123Scan), software development kits (SDK) and other scanner applications. Ken has been with Zebra for over 20 years. Prior to working for Zebra, Ken worked for the Xerox Corporation for eight years as a Senior System Engineer.

Ken holds a B.S. in Mechanical Engineering from Purdue University, West Lafayette, Indiana and an M.S. in Electrical Engineering from the University of Rochester, Rochester, New York.